Non-Construction Applications

US Plywood and OSB in Non-Construction Applications

US plywood and OSB structural panels are frequently used in non-construction applications as some of the same performance requirements are also applicable. This ranges from upholstered furniture to shelving, site hoardings, protective cargo linings and packaging.

Find out more about the benefit of structural panels in non-construction applications, startubg with our dedicated performance panel website. For info on how these panels add value in a range of industrial applications, see the ‘Performance Panels’ brochure (available in English and Spanish).

Factors to be considered when choosing wood-based panels would be:

• Appearance/surface quality

• Strength and stiffness to resist any applied loads

• The quality of adhesive to match the end-use environmental conditions

• Ease of workmanship

• Adequate service life

• Cost effectiveness

Know Your Product’s Industrial Category Index (ICI)

Before you can specify the right grade or type, you need to know a product’s Industrial Category Index (ICI). This is derived from the series of four numbers on a panel which refer to different face, back, crossband and inner lay characteristics.

APA’s Industrial Panel Selection Guide helps you work this out. It consists of four worksheets with a series of simple ‘yes and no’ questions. Once answered, you will be given the ICI for the most suitable product.

Packaging/materials handling

| Type of application | Suitable product | Important considerations |

|---|---|---|

| Boxes, packing cases (crates) | Plywood OSB | Strength & Stiffness Fastener holding Impact resistance Moisture resistance |

| Agricultural containers e.g. potato boxes | Plywood | Strength & stiffness Fastener holding Impact performance Moisture resistance Durability Stacking height1 |

| Pallets - Solid deck pallets - Plywood slave pallets2 | Plywood OSB | Strength & stiffness Racking resistance Fastener holding Impact resistance Moisture resistance Durability |

| Notes 1 The number of boxes which can be stacked on top of one another when fully loaded. This is often an issue for the design of the finished product rather than the individual components from which it is box is manufactured. 2 Optional edge protection may need to be considered |

||

Site hording

| Type of application | Suitable product | Important considerations |

|---|---|---|

| Perimeter hoarding | Plywood OSB | Appearance/surface quality Strength & stiffness (wind loading) Fastener holding Moisture resistance Ability to take a paint finish Potential for re-use |

Furniture

| Type of application | Suitable product | Important considerations |

|---|---|---|

| Kitchen units | Plywood | Appearance/surface quality Strength & stiffness Moisture resistance Screw holding |

| Storage units/lockers | Plywood | Appearance/surface quality Strength & stiffness Moisture resistance Ability to take adhesives Screw holding |

| Kitchen worktops | Plywood | Surface quality Strength & stiffness Impact resistance Moisture resistance Dimensional stability |

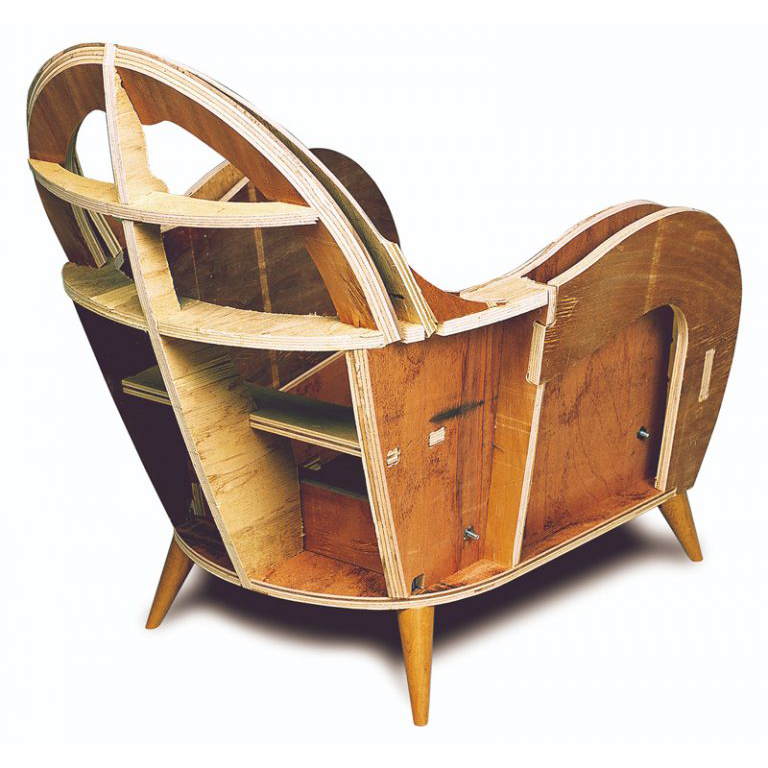

| Upholstered furniture framing | Plywood OSB | Strength & stiffness Screw holding Ability to take adhesives Dimensional stability |

Industrial shelving

| Type of application | Suitable product | Important considerations |

|---|---|---|

| Storage shelving | Plywood • Sanded from strongest, Group 1 species eg Grade B-D, Exposure1 Grade B-C Exterior A-D Exposure 1 A-C Exterior • Rated Sturd-I-Floor • Unsanded Rated Sheathing • Medium Density Overlay (MDO) • High Density Overlay1(HDO) OSB Unsanded Rated Sheathing | Strength & stiffness Panel thickness Panel deflection to load Support centres Durability Optional edge protection |

| Note: 1 Advisable for surfaces that need frequent cleaning |

||

Truck/Van Linings for cargo bays

| Type of application | Suitable product | Important considerations |

|---|---|---|

| Dry linings1 | Plywood Overlaid plywood2 | Strength Durability Smoothness of face |

| Wet linings | Plywood (preservative treated) [Recommend APA Series V-6113 exterior panels] | Strength & stiffness Durability Smoothness/surface quality |

| Notes: 1 Linings are ordinarily subjected to extremely rough usage so many factors govern material selection 2 Plywood overlaid with metal or fibreglass-reinforced plastic (FRP) 3 All veneer plywood manufactured to Product Standard PS1 suitable for preservative treatment |

||

Industrial Panel Selection Guide

APA’s Industrial Panel Selection Guide

The Industrial Panel Selection Guide (download here) helps you complete your specification. These notes tell you how to work with it.

The guide is a series of ‘yes’ and ‘no’ questions in four worksheets to help you decide which plywood or OSB product you will need. For example, it asks you if your application requires smoothness or overlays; it asks about uestion of size and number of knots and knot holes and whether the panel must be suitable for painting and staining and so forth.

For every ‘yes’ answer you circle the number given in the right hand column. Then, when you have answere all the qautionYou take the highest numbers for each worksheet to determine your APA Industrial Category Index.

For example, if the highest circled numbers are 7 on the first worksheet, 1 on the second, 3 on the third and 1 on the fourth, the Industrial Category Index for the required panel is 7-1-3-1. You then identify your panel by matching your numbers in the Panel Translator Chart or Characteristics Locator Charts.

Guide to worksheets

Worksheet 1 : Panel face characteristics

Worksheet 2: Panel back characteristics

Worksheet 3: First crossband characteristics

Worksheet 4: Inner layer characteristics

Panel Translator Chart

Characteristics Locator Charts

Substitute Panels

If a panel with the Industrial Category Index for your application is not available as one of the common APA panel construction grades, it is possible to select a substitute panel. Because the Industrial Category Index identifies minimum acceptable characteristics, any panel with Characteristic Numbers in each category equal to or greater than the original number may be substituted.

For instance, if an application calls for a panel with an Industrial Category Index of 10-10-3-3, a panel with the number 10-10-9-9 would also work. However, a panel number of 10-9-9-9 would be unacceptable because the second number is lower than the second number in the original Industrial Category Index.

Additional publications available from www.apawood-org:

Packaging & industrial shelving: Industrial Use Guide – Material Handling (Form No. M200A)

Pallets: Engineered Wood Pallets – A Solid Value (Form No. T200) and Industrial Use Guide – Plywood pallets in Automated Storage and Retrieval Systems (Form No. S225)

Furniture: Upholstered Furniture Frames (Form B625)

Truck/van linings for cargo bays: Transport Equipment (Form No. G210).