Engineered Wood Shapes Washington State History

A massive renovation project on the University of California, Berkeley campus brought the historic California Memorial Stadium up to modern standards.

View Case Study

Historical Stadium Meets Modern Standards with Overlaid Plywood Forms

A massive renovation project on the Berkeley campus at the University of California brought the historic California Memorial Stadium up to modern standards. Built in 1923, the aging facility required renovations and a seismic retrofit to reduce seismic risk while …

View Case Study

Engineered Wood Formwork is Cost-Effective, Customizable for Apartment Buildings

Affordability was a primary factor for Rush Commercial when making the concrete forming product selection for the construction of the Pacifica Apartments in Tacoma, Washington. The two-building, 230,000-square-foot apartment complex featured 177 units, two underground parking garages, and required 7,000 …

View Case Study

California Apartments Showcase Value Engineering

The 120-unit, seven-building complex were re-engineered with glulam and wood-framed shear walls to keep framing costs manageable.

View Case Study

Scenic Setting for Cross Laminated Timber Office

Faction Projects developed, designed and built their new, 14,000 square-foot office building in Canada’s scenic Kelowna region, British Columbia. Cross-laminated timber was an ideal material with its slim profile, fire resistance ratings, ease of installation and beauty. The building is framed with glulam post and beam, with CLT making up the floor and roof systems. The resulting three-storey structure is therefore respectful of its surroundings, yet modern in its angles and appearance.

View Case Study

Natural Beauty of Placer River Trail Bridge

Set in the remote Alaskan forest, the 280-foot camelback truss bridge is the longest clear span glulam timber truss bridge in North America. It connects visitors to the remote wilderness. The design by Western Wood Structures was chosen for its natural beauty, cost effectiveness and durability in the harsh climate. As it is close to Spencer Glacier, the bridge had to be constructed high enough to allow any icebergs to float safely underneath without collision.

View Case Study

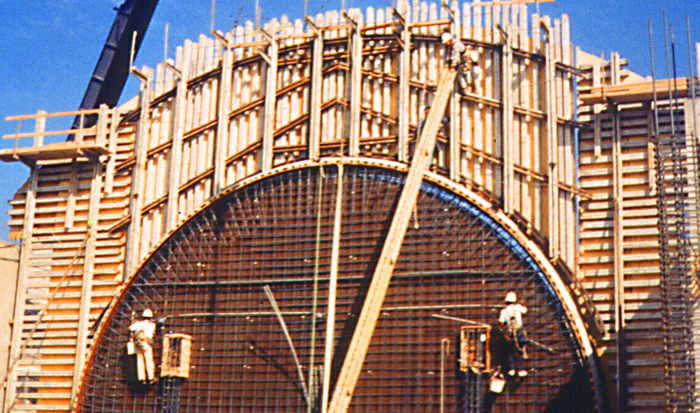

Cathedral of Christ the Light

This massive glulam and glass structure in Oakland, California, was created by engineers usingd innovative computer modelling backed by field tests to achieve the high strength and ductility requirements for a building located less than eight miles from a major fault zone.

View Case Study

Portland’s One North Development Connects Vision with Community

The three structures comprising the One North office development surround a 14,000 square foot courtyard, offering open access to the local community. The design focuses on the use of engineered wood (from glulam beams to plywood shear walls) to deliver …

View Case Study

The Largest Cross Laminated Timber Structure in America

America’s largest cross laminated timber (CLT) structure is to be found in the state of Oregon. The new First Tech Federal Credit Union building has a CLT roof, floors and simplified support for the exterior façade, with glulam for the …

View Case Study

Mass Timber Has Banks Seeing Green

First United Bank wanted its new American offices to align with the bank’s sustainability initiative. Gensler architects responded with an innovative design and building materials. “The bank wanted buildings that really showed how they were built and related to their …

View Case Study

Beauty and the Budget

The word is out regarding engineered wood. Strong. Environmentally responsible. Cost-efficient. Known for its natural warmth and aesthetic appeal. These qualities have inspired the work of LEVER Architecture, the Oregon-based practice with a reputation for using wood in new and …

View Case Study