OSB

Oriented Strand Board

OSB shares many of the strength and performance characteristics of plywood. The combination of wood and adhesives creates a strong, dimensionally stable panel that resists deflection, delamination, and warping.

Relative to their strength, OSB panels are light in weight and easy to handle and install. They are able to resist racking and shape distortion when subjected to strong wind and seismic conditions.

Panels produced by APA member mills are manufactured to PS2-18, the US Voluntary Product Standard PS2 – Performance Standard for Wood-based Structural-Use Panels. This sets the performance requirements based on the panels intended end use in load-bearing applications.

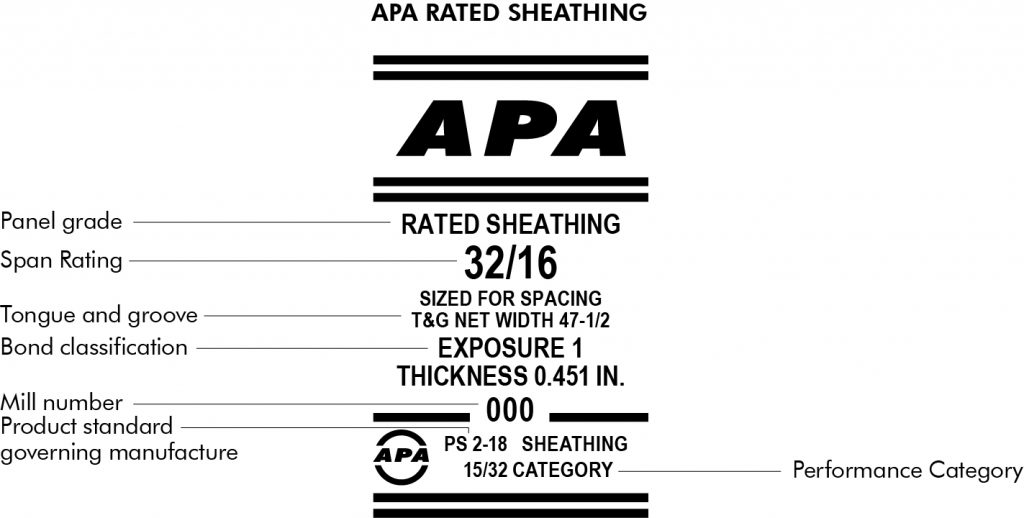

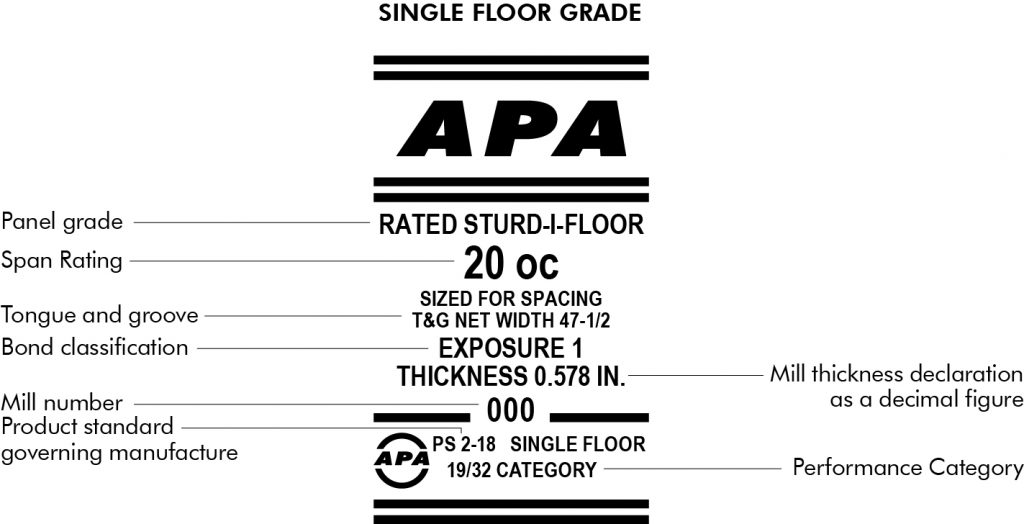

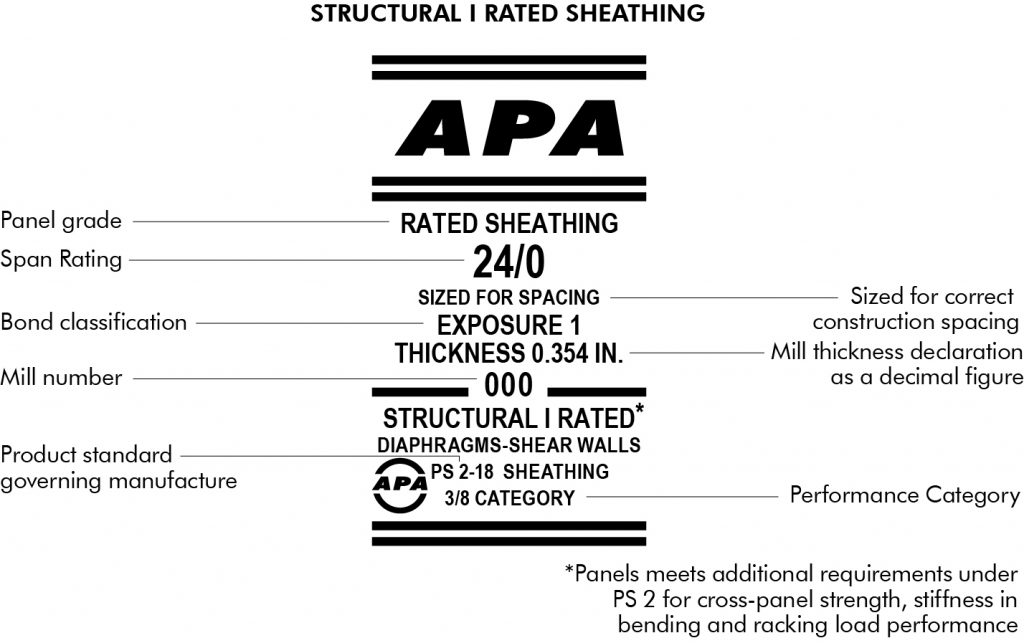

APA-trademarked OSB can be used for a variety of structural uses including subflooring, single-layer flooring, walls and roof sheathing. The panel grade on the trademarked panel refers to the intended application, for example: Rated Sheathing, Rated Sturd-I-Floor.

These performance rated panels can also be used for non-construction purposes as some of the same performance requirements are also applicable for industrial applications.

APA’s Global Technical Support Desk

Engineered wood experts are available to answer your questions about the specification and application of APA products. Contact our global help desk or call +1 253 620 7400.

OSB Trademarks

Understanding APA Trademarks for OSB

To find out what the different markings mean, click one of the following:

APA Rated Sheathing

Rated Sturd-I-Floor (Single Floor Grade)

Structural I Rated Sheathing

OSB Panel Grades

APA OSB Panel Grades for Different Applications

The main APA OSB panels are: APA Rated Sheathing, Structural 1 Rated Sheathing and APA Rated Sturd-I-Floor. See more technical information on spacing for support and loadbearing.

APA OSB panels are manufactured to Exposure 1 standards, equivalent to the UK and European OSB/2 classification for load bearing panels for use in dry conditions. Trademark examples.

APA OSB is not intended for exterior use and only two classes are relevant: Use Class 1 – dry, interior and Use Class 2 – interior or undercover, not exposed to the weather, but condensation possible. See additional moisture content guidance and aligning Use and Service Classes.

This is a basic, unsanded sheathing grade for wall, roof, sub-flooring and industrial applications such as pallets and engineering design with proper capacities.

‘Structural I’ on an APA trademark for OSB sheathing and Sturd-I-Floor shows it is a performance-rated panel, with superior bending stiffness and strength. More. It will have been produced to meet the requirements of US standard PS 2 -18 for cross-panel strength and stiffness in bending and racking load performance.

APA Rated Sturd-I-Floor

A single layer floor decking comprising of a combination of subfloor-underlayment. It provides a smooth surface for application of carpet or pad. This touch-sanded panel is available either as a square edged panel or with a tongue and groove on the two long edges. It offers high concentrated and impact load resistance during construction and occupancy.

Span Rating on OSB panels

Span Rating on APA Trademarked OSB Panels

The Span Rating denotes the maximum permitted centre to centre spacing of supports. It is particularly important for Rated Sheathing and Rated Sturd-I-Floor when the long panel dimension or strength axis is across two or more supports. See technical specifications for Sheathing, Rated Sturd-I-Floor and Structural 1.

What span ratings mean

The trademark gives this as a fraction (in inches), such as 32/16. The number on left denotes the maximum centre to centre spacing of supports (in inches) when the panel is used for roof sheathing (sarking). Number on right denotes the maximum centre to centre spacing when the panel is used for subflooring.

Sheathing panels with a roof span rating of 24 or greater may be used vertically or horizontally as wall sheathing over studs at 24 inch centres. Those with roof Span Ratings of less than 24 inches may be used vertically or horizontally over studs spaced at 16 inches on centre.

Panels denoted as Wall-16 or Wall-24 have been specifically manufactured for use as wall sheathing over studs spaced at the designated distance apart.

APA Rated Sturd-I-Floor panels are specifically for single layer flooring applications where a solid face is required. They are manufactured with Span Ratings of 16, 20, 24, 32 and 48 o.c.

Allowable uniformly distributed live load at maximum span

100 lbs/ft2 (1.48 kN/m2) plus a further 10 lb/ft2 (0.15 kN/m2) dead load.

For Rated Sheathing a further 30 lb/ft2 (0.45 kN/m2) can be carried as snow load. Sheathing with a span rating of 48/24 or more can additionally carry a snow load of 35 lb/ft2 (0.52 kN/m2).

Sturd-I-Floor 48oc can take a total load of 65 lbs/ft2 (0.97 kN.m2).

OSB Exposure 1 Bond Durability

Exposure 1 Bond Durability for APA OSB Panels

All APA trademarked OSB panels are manufactured to Exposure 1 standards, equivalent to the OSB/2 classification in UK and EU standards for load bearing panels used in dry conditions.

Bond classification relates to the moisture resistance of the glue bond and therefore the structural integrity of the panel. It does not relate to physical (erosion, ultraviolet etc.) or biological (mould, fungal decay, insect etc.) resistance of the panel.

- Exposure 1/OSB/2 panels are not adversely affected by moisture under the internal conditions of Service Class 1 or 2 environments found in Eurocode 5. APA’s guide to Service Classes and moisture environments, is here.

- Exposure 1 panels have the same adhesive as exterior plywood panels but are not suitable for long-term exposure to the weather.

- They are able to resist the effects of moisture due to construction delays, or other conditions of similar severity.

- OSB/2 is defined in (BS) EN 300.

Sized for Spacing

Sized for Spacing on an APA Trademark

OSB, like all wood products, will expand or shrink slightly with changes in moisture content. If the wood structural panels are tightly butted, there is no room for expansion and buckling can occur

APA usually recommends a 3mm (1/8-inch) space between panel edge and end joints and indicates this on its trademark by the words ‘Sized for Spacing’.

This tells the customer that the panel has been produced to a size slightly less than the traditional nominal 1220mm (48″) by 2440mm (96″). Standard panels tolerances are + or – 3mm (1/8”).

This is done to facilitate proper panel spacing and not to circumvent manufacturing tolerances. Click here for APA ‘s Technical Topic on the tolerances allowed by each US standard. Also, see examples of APA’s OSB trademarked panels.

Tongue and Groove

Tongue and Groove (T&G) on APA Panel

The Tongue and Groove (T&G) marking on an APA trademarked panel indicates that it has a tongue and groove profile on its two long edges; and that this is to an APA approved pattern.

See examples on APA trademarked OSB panels.

Technical Notes

- This T&G profile removes the need for support (blocking) under adjacent panel edges to prevent them from deflecting independently of each other when load is applied.

- The material removed to create the tongue normally reduces the width of the panel by approximately 12.5 mm (1/2”), therefore, the net width of the panel may be 47-1/2” (1206 mm).

Selecting Your OSB Panel

Selecting Your Panel – Structural 1, APA-Rated OSB Sheathing and Sturd I -Floor

APA’s technical specification overview compares the three main types of APA OSB panels – Rated OSB Sheathing, Structural 1 and APA Rated Sturd I -Floor. It gives data for the most common performance categories, span ratings, and thickness tolerances.

See how this info appears on APA OSB trademarked panels. When you see Structural I on an APA trademark for OSB sheathing and Sturd-I-Floor it denotes a performance-rated panel, with superior bending stiffness and strength. See more on its strength benefits.

| PERF CAT | APA RATED SHEATHING | STRUCTURAL 1 | APA RATED STURD I-FLOOR | Specific tolerances in PS2 & recommended thickness denoted on APA Trademarked Panels | ||

|---|---|---|---|---|---|---|

| On standard/ trademarked panel | Span Rating | Span Rating | Span Rating | Min Thickness (In) | Max Thickness(In) | Recommended thickness (in) |

| 3/8 | Wall 16 oc/ Wall 24 oc/ 24/0 | 24/0 | N/A | 0.344 | 0.406 | 0.354 |

| 7/16 | Wall 16 oc/ Wall 24 oc/ 24/16 | 24/16 | N/A | 0.406 | 0.469 | 0.418 |

| 15/32 | 32/16 | 32/16 | N/A | 0.438 | 0.500 | 0.451 |

| 1/2 | 32/16 | 32/16 | N/A | 0.469 | 0.531 | 0.483 |

| 19/32 | 40/20 | 40/20 | 16 oc/ 20 oc | 0.563 | 0.624 | 0.578 |

| 5/8 | 40/20 | 40/20 | 16 oc/20 oc | 0.594 | 0.656 | 0.609 |

| 23/32 | 48/24 | 48/24 | 24 oc | 0.688 | 0.750 | 0.703 |

| 3/4 | 48/24 | 48/24 | 24 oc | 0.719 | 0.781 | 0.734 |

| 7/8 | 60/32 | N/A | 24oc/ 32 oc | 0.831 | 0.919 | 0.849 |

| 5/16 | 12/0, 16/0, 20/0 | N/A | N/A | 0.281 | 0.344 | 0.289 |

| 1-1/8 | N/A | N/A | 48 oc | 1.069 | 1.181 | 1.091 |

OSB Panels, Strength Comparisons

Comparison of APA’s Structural OSB Panels

‘Structural I’ on an APA trademark for OSB sheathing and Sturd-I-Floor indicates that it is a performance-rated panel, compared to basic rated panels. It also denotes that it meets the specific requirements of US Performance Standard PS – 18 for cross-panel strength and stiffness in bending and racking load performance.

Use our comparison tables to check the superior bending stiffness and strength for OSB Structural I sheathing and Sturd-I-Floor.

OSB Rated Structural 1 panel and basic OSB Rated Sheathing (roof and subfloor sheathing)

OSB Structural I panel and basic OSB Rated Sturd-I-Floor (flooring)

The further the supports are spaced, the thicker the panel may have to be. For more on span ratings and performance categories for OSB panels, see here.

Bending Stiffness Comparison, Sheathing

| STRESS APPLIED PARALLEL TO STRENGTH AXIS1 | STRESS APPLIED PERPENDICULAR TO STRENGTH AXIS1 | SPAN RATING | PERFORMANCE CATEGORY | PREDOMINANT THICKNESS LABEL | ||

|---|---|---|---|---|---|---|

| Rated Sheathing | Structural I Sheathing | Rated Sheathing | Structural I Sheathing | |||

| 60,000 | 60,000 | 11,000 | 17,600 | Roof-24 | 3/8 | 0.354 IN |

| 78,000 | 78,000 | 16,000 | 25,600 | Roof-24 Subfloor-16 | 7/16 | 0.418 IN |

| 115,000 | 115,000 | 25,000 | 40,000 | Roof-32 Subfloor-16 | 15/32 | 0.451 IN |

| 225,000 | 225,000 | 56,000 | 89,600 | Roof-40 Subfloor-20 | 19/32 | 0.578 IN |

| 400,000 | 400,000 | 91,500 | 146,600 | Roof-48 Subfloor-24 | 23/32 | 0.704 IN |

| Note:¹ The strength axis is parallel to the face and back orientation of the strands unless otherwise indicated. | ||||||

Bending Strength F S (lb-in²/ft of panel width)

| STRESS APPLIED PARALLEL TO STRENGTH AXIS1 | STRESS APPLIED PERPENDICULAR TO STRENGTH AXIS1 | SPAN RATING | PERFORMANCE CATEGORY | PREDOMINANT THICKNESS LABEL | ||

|---|---|---|---|---|---|---|

| Rated Sheathing | Structural I Sheathing | Rated Sheathing | Structural I Sheathing | |||

| 300 | 300 | 97 | 145.5 | Roof-24 | 3/8 | 0.354 IN |

| 385 | 385 | 115 | 172.5 | Roof-24 Subfloor-16 | 7/16 | 0.418 IN |

| 445 | 445 | 165 | 247.5 | Roof-32 Subfloor-16 | 15/32 | 0.451 IN |

| 750 | 750 | 270 | 405 | Roof-40 Subfloor-20 | 19/32 | 0.578 IN |

| 1,000 | 1,000 | 405 | 607.5 | Roof-48 Subfloor-24 | 23/32 | 0.704 IN |

| Note: 1 The strength axis is parallel to the face and back orientation of the strands unless otherwise indicated. | ||||||

Sturd-I-Floor comparisons – OSB Bending Stiffness EI (lb-in²/ft of panel width)

| STRESS APPLIED PARALLEL TO STRENGTH AXIS1 | STRESS APPLIED PERPENDICULAR TO STRENGTH AXIS1 | SPAN RATING | PERFORMANCE CATEGORY | PREDOMINANT THICKNESS LABEL | ||

|---|---|---|---|---|---|---|

| Rated Sheathing | Structural I Sheathing | Rated Sheathing | Structural I Sheathing | |||

| 150,000 | 150,000 | 34,000 | 54,400 | 16 oc | 19/32 | 0.578 IN |

| 210,000 | 210,000 | 40,500 | 64,800 | 20 oc | 19/32 | 0.578 IN |

| 300,000 | 300,000 | 80,500 | 128,800 | 24 oc | 23/32 | 0.704 IN |

| 650,000 | 650,000 | 235,000 | 376,000 | 32 oc | 7/8 | 0.849 IN |

| 1,150,000 | 1,150,000 | 495,000 | 792,000 | 48 oc | 1-1/8 | 0.1.091 IN |

| Note:1 The strength axis is parallel to the face and back orientation of the strands unless otherwise indicated. | ||||||

Bending Strength F S (lb-in²/ft of panel width)

| STRESS APPLIED PARALLEL TO STRENGTH AXIS1 | STRESS APPLIED PERPENDICULAR TO STRENGTH AXIS1 | SPAN RATING | PERFORMANCE CATEGORY | PREDOMINANT THICKNESS LABEL | ||

|---|---|---|---|---|---|---|

| Rated Sheathing | Structural I Sheathing | Rated Sheathing | Structural I Sheathing | |||

| 500 | 500 | 180 | 270 | 16 oc | 19/32 | 0.578 IN |

| 575 | 575 | 250 | 375 | 20 oc | 19/32 | 0.578 IN |

| 770 | 770 | 385 | 577.5 | 24 oc | 23/32 | 0.704 IN |

| 1,050 | 1,050 | 685 | 1,027.5 | 32 oc | 7/8 | 0.849 IN |

| 1,900 | 1,900 | 1,200 | 1,800 | 48 oc | 1-1/8 | 0.1.091 IN |

| Note:1 The strength axis is parallel to the face and back orientation of the strands unless otherwise indicated. | ||||||

Formaldehyde Facts, OSB

Understanding Formaldehyde in OSB Panels

APA oriented strand board (OSB) is manufactured using phenol formaldehyde or MDI (diphenylmethane di-isocyanate) adhesives. They are water proof, extremely stable and highly durable with very low formaldehyde emissions.

For APA’s latest guide, Formaldehyde and Engineered Wood Products, download here.

OSB panels manufactured in accordance with US Voluntary Product Standard PS2 -18 easily meet the E1 formaldehyde emission limit of 0.124mg/m3 requirement of UK and European standards, (BS) EN 300 and (BS) EN 13986. Also see how APA products meet requirements of the Japanese Agricultural Standard for Formaldehyde Emission (JAS) and California Air Resource Board (CARB).

Japanese regulation for formaldehyde emissions from wood panels is widely considered the most stringent in the world. The JAS standards for plywood and Structural Panels (OSB) do not directly specify a limit for formaldehyde emissions.

However, panels meeting the F**** standard for formaldehyde emissions (the most stringent requirement level) are required to have an average emission level below 0.30mg/l as tested to Japanese Standard JIS A 1460.

APA member products are exempt from the ‘Airborne Toxic Control Measure to Reduce Formaldehyde Emissions from Composite Wood Products’. The CARB regulation was used as the basis for the latest Federal (US National) Regulation, so the same exemption exists for both.

Section 93210 (c) (8) of the measure specifically states that this excludes:

- Structural plywood as specified in the Voluntary Product Standard – Structural Plywood (PS 1-19).

- Structural panels as specified in the Voluntary Product Standard – Performance Standard for Wood-Based Structural-Use Panels (PS 2-18, sometimes designed by APA on its panels by APA’s own Performance-Rated Panel Standard – PRP 108).

- Structural composite lumber (LVL) specified in Standard Specification for Evaluation of Structural Composite Lumber products (ASTM D 5456-06).

- Oriented strand board.

- Prefabricated wood I-joists as specified in Standard Specification for Establishing and Monitoring Structural Capacities of prefabricated Wood I-Joists (ASTM D 5055-05).